Strainer pressure drop calculation pdf Wallenstein

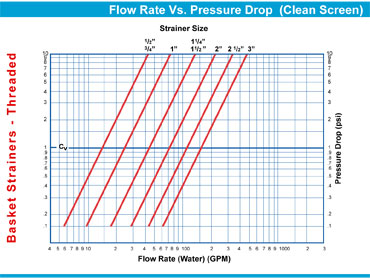

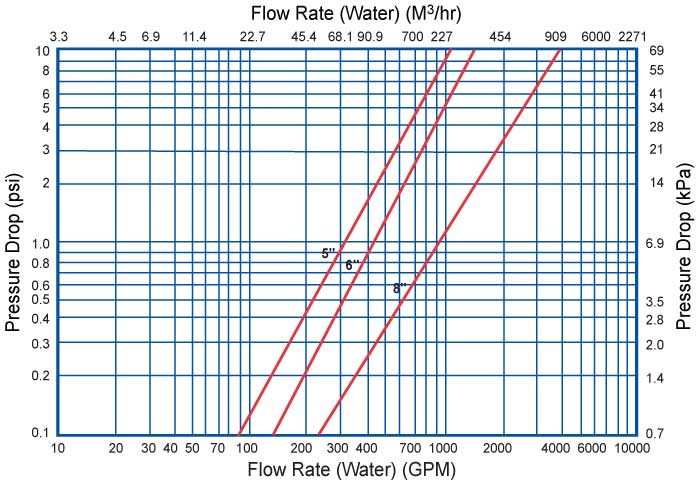

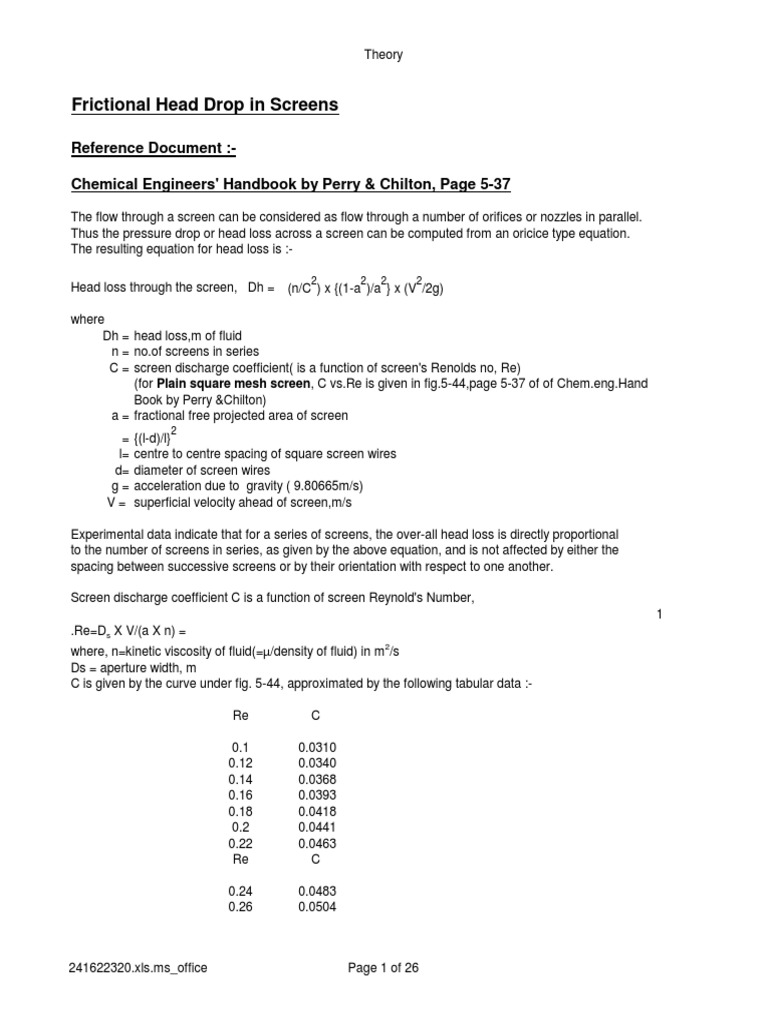

Standard Cast Pipeline Strainers PRESSURE DROP CHART Temporary Cone and Basket Strainers (TC, TB) KECKLEY This pressure drop chart is based on the flow of clean water through the Keckley Strainer Styles listed above with screen perforations ranging from 1/16” through 1/8”. TO USE CHARTS: Find your desired rate of flow (GPM) on the left hand side of the chart. Follow its corresponding horizontal line to the point where it

Pressure drop in pipes adpf

Pressure Drop Charts Check Valves Pressure Drop Charts. 22/12/2005В В· I dont think that at 150% of open area there is going to be a significant pressure drop. When the strainer becomes clogged there will be a presure drop worth considering. Idelchik Ch8 Flow Resistance A Design Guide for ENgineers covers such devices with uniform openings that cross the flow path. I am a busy at the moment so cant do the, servicing strainer C. Optional manual or auto blow-down Y Type Strainers - Threaded Y Type Strainers - Flanged Y Strainers Flow Rate Vs. Pressure Drop (Clean Screen) Note: These charts are for theoretical calculations ONLY. Please contact our office with your exact specifications and you will be provided with factory calculations..

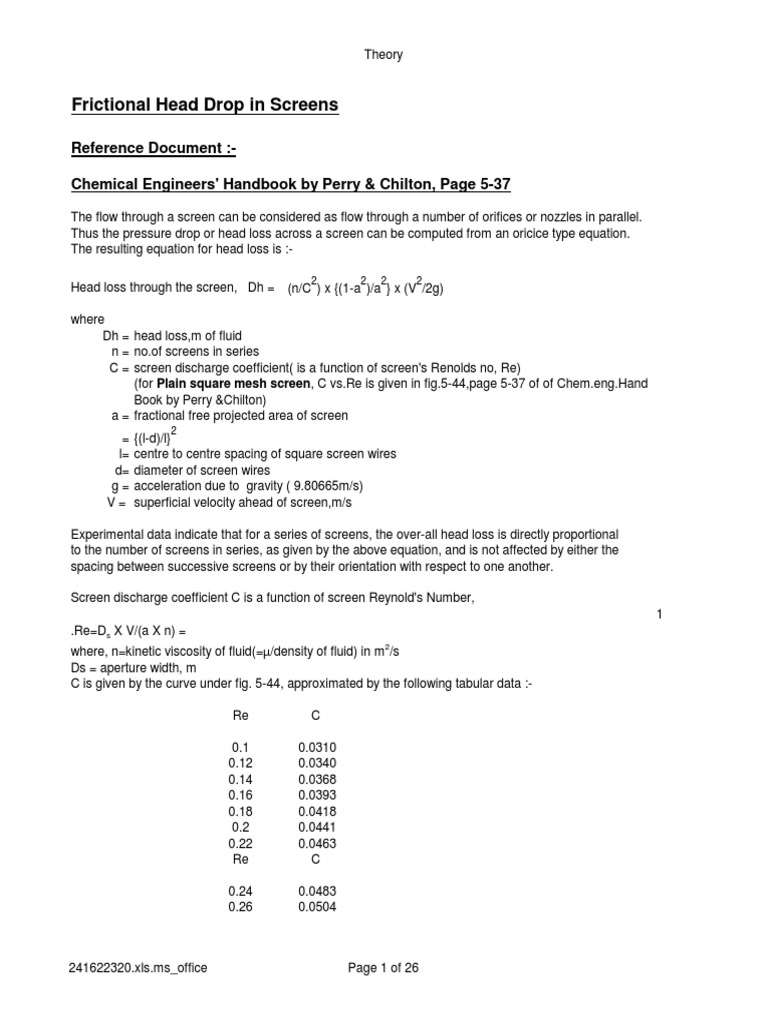

calculation, for example you are missing the pressure drop across the cleaner, the properties of the fluid, etc. Figure 4 The control volume determines where the conditions on the suction side of the pump can be calculated. Figure 5 A system that requires a specified pressure at the inlet of an equipment. l) Determine the pressure drop (PI) through the strainer with water flow and standard screens. 2) If non-standard screens (i.e. 40 mesh, etc.) are being used, apply factors in Chart #1 to determine corrected pressure drop (P2). 3) Multiply PI or P2 (if used) by the specific gravity of the fluid actually flowing through the strainer to get P3.

Fig. 822 & 810 (922 & 910) Y-Type Strainers; Y-Type Strainers. See The Full Strainers Range Here Fig. 822 & 810 (922 & 910) Fig. 822 & 810 (922 & 910) Features & Benefits Higher Kv (flow factor) for reduced pressure drop compared to previous range. * Please refer to Datasheet for full technical information . Pressure Rating PN16. Product Material Cast/ Ductile Iron Pressure Drop Curves. Fabricated Basket Strainers; Casted Y Strainers; Fabricated Y Strainers; Fabricated T Strainers; Conical Strainers 20-125mm; Conical Strainers 150-1200mm; Burst Pressure Calculation. Basket, Tee, Duplex Strainers; Y Strainer; Cover Head; Pressure Drop Calculation; Screen Opening; Blog / News; Contact Us

Flow Rate Vs. Pressure Drop (Clean Screen) These curves are for clean baskets, without mesh liners – and with WATER flowing through the strainer. For mesh-lined baskets and/or other fluids, you must first compute a correction factor. Pressure Drop Online Calculator for Mobile and PDA-----Element of pipe: Strainers and grids / Y-Strainer

The pressure loss across a strainer can be calculated using the system’s flow rate and the Cv factor for that strainer. For example, a 1" Model 72 simplex strainer with a perforated basket has a Cv factor of 22.5. In water service with a 30 gpm flow rate, it will have a 1.7 psi pressure drop (30 ÷ 22.5)2 = 1.7. Pressure Drop Charts - "Y" Type Strainers (Cast) THREADED AND WELD END "Y" TYPE STRAINERS (YS12, YS52, YS55, YS56, YS81, YS82, YS83, YS84, YS63, YS65) Flow Rate - GPM (Clean Screen Handling Water) Pressure Drop - PSI 11.52 345 678910152 345 6 7891001502 34 567891000 Size(in) ½ ¾1 1¼ 1½ 22½3 4 10 9 8 7 6 5 4 3 2 1.5 1.0.9.8.7.6.5.4.2.15.1.3 vC FLANGED END "Y" TYPE STRAINERS (YS58, YS59

Pressure Drop Calculations To accurately calculate the pressure loss for filters and strainers in a pipeline, proceed as follows: First calculate pressure loss using Cv factor formula at right; Take the pressure loss figure obtained in (1) and recalculate it using the … pressure drop through the strainer will increase very rapidly, possibly causing damage to the screen. Screen openings other than those shown above are readily available. Various mesh sizes as fine as 5 micron and perforated plate as coarse as 1/2” Dia. are in inventory. Screens are available in a wide range of materials. Screens of carbon steel, stainless steel (304, 316), alloy 20, monel

pressure drop through the strainer will increase very rapidly, possibly causing damage to the screen. Screen openings other than those shown above are readily available. Various mesh sizes as fine as 5 micron and perforated plate as coarse as 1/2” Dia. are in inventory. Screens are available in a wide range of materials. Screens of carbon steel, stainless steel (304, 316), alloy 20, monel The Pressure Drop Chart for Basket strainers indicates a drop of 0.9psi. The Screen openings chart indicates the % open area of 100 mesh is 30%. From chart one correction factor to be 1.2.

Pressure drop in pipes.... PRESSURE DROP CALCULATIONS Pressure drop or head loss, occurs in all piping systems because of elevation changes, turbulence caused by abrupt changes in direction, and friction within the pipe and fittings. The most common methods used to determine the head loss in fiberglass pipe are Hazen-Williams, Manning and Darcy-Weisbach equations. The suitability of each On strainer devices all data published by Hays is for a new, unclogged strainer. The variation in materials that clog a strainer makes it virtually impossible to predict pressure drops for clogged strainers. In system design it is recommended that a reasonable allowance be made for an additional restriction above that of the clean strainer.

Pressure drop curves are based on water flow with standard screens. See page 16 for correction factors to be used with other fluids and/or screen openings. 2. For Style 1 basket strainers multiply value obtained in figure 2 by 1.15 to obtain clean pressure drop. FIGURE 1 FIGURE 2 Threaded Basket Strainer Pressure Drop - Liquids (Sizes 1/ 2 - 1 Pressure Drop Online Calculator for Mobile and PDA-----Element of pipe: Strainers and grids / Y-Strainer

Technical Information for Standard Cast Pipeline Strainers. Performing pressure drop calculations are essential for deciding which pipeline strainer is best for your liquid filtration application. Pressure drops for Models 30, 50, 510, 570 and 72 strainers are all available and in ISC Sales’ inventory. and represented in table V. As William Hooper [8] has not provided any details about the pressure drop due to Y-strainer, therefore pressure drop due to Y-strainer is calculated using equivalent length method as per details provided in Carrier system design manual [2]. Pressure drop due to straight pipe is calculated using equation (1). TABLE V

For example, do not select Strainer model Wye-tpe, size say 1/2"-1/2", quatity 1 in first column and select the same model type and size in second column with quatity 1 to calculate the pressure drop for two same strainer type with same size. In that case, the pressure drop will only be calculated based on the quantity mentioned in first column Pressure Drop Chart System fluid passing through a Spirovent or Spirotrap will create a certain pressure drop, depending on the size of the nozzles, diameter of the shell, and the volume (flow) and speed (velocity) of the fluid. Figures D-1 and D-2 (pages 3 and 4) show the pressure drops and water velocities for all product sizes up to

Select a strainer of the same nominal size as that of the piping to which it will be connected (nominal size of piping = nominal size of strainer). Please remember that using a strainer of a smaller nominal size increases the pressure loss of the strainer and may disable it from keeping specified pressure at … a clean basket from curve on appropriate Pressure Drop Chart in the Technical Data Section (flanged end). At 1000 GPM of water the pressure drop is .4psi. As described above the multiplying factor for a 50% clogged basket is 2. The pressure drop is then .4psi x 2 = .8psi. S-MS-PressureDropClog Theoretical Pressure Drop Curve for Screen Clogging

PRESSURE DROP CHARTS WYE & BASKET STRAINERS

Technical brochure Strainers FA. and represented in table V. As William Hooper [8] has not provided any details about the pressure drop due to Y-strainer, therefore pressure drop due to Y-strainer is calculated using equivalent length method as per details provided in Carrier system design manual [2]. Pressure drop due to straight pipe is calculated using equation (1). TABLE V, Pressure Drop Online Calculator for Mobile and PDA-----Element of pipe: Strainers and grids / Y-Strainer.

Titan Pressure Drop Calculations. Strainers normally present low resistance to liquid flow. The pressure drop across most strainers is relatively small compared with the pressure drop across thick media filters or membrane filters. Another difference is the function. A strainer is used to protect other downstream equipment (e.g., pumps, instrumentation) from damage by rogue, Flow Rate Vs. Pressure Drop (Clean Screen) These curves are for clean baskets, without mesh liners – and with WATER flowing through the strainer. For mesh-lined baskets and/or other fluids, you must first compute a correction factor..

S-MS-PressureDrop-Y Pressure Drop Chart Watts Water

Pressure Drop Chart Temporary Cone and Basket Strainers. For example, do not select Strainer model Wye-tpe, size say 1/2"-1/2", quatity 1 in first column and select the same model type and size in second column with quatity 1 to calculate the pressure drop for two same strainer type with same size. In that case, the pressure drop will only be calculated based on the quantity mentioned in first column Pressure Drop In Valves & Strainers Pressure drop calculations can be made for valves and strainers for different fl uids, fl ow rates, and sizes using the CV values and the following equation: Where: P = Pressure drop in PSI; feet of water = PSI.4332 G = Gallons per minute C V = Gallons per minute water per 1 PSI pressure drop Sg = Specifi.

Strainers normally present low resistance to liquid flow. The pressure drop across most strainers is relatively small compared with the pressure drop across thick media filters or membrane filters. Another difference is the function. A strainer is used to protect other downstream equipment (e.g., pumps, instrumentation) from damage by rogue l) Determine the pressure drop (PI) through the strainer with water flow and standard screens. 2) If non-standard screens (i.e. 40 mesh, etc.) are being used, apply factors in Chart #1 to determine corrected pressure drop (P2). 3) Multiply PI or P2 (if used) by the specific gravity of the fluid actually flowing through the strainer to get P3.

The pressure loss across a strainer can be calculated using the system’s flow rate and the Cv factor for that strainer. For example, a 1" Model 72 simplex strainer with a perforated basket has a Cv factor of 22.5. In water service with a 30 gpm flow rate, it will have a 1.7 psi pressure drop (30 ÷ 22.5)2 = 1.7. PRESSURE DROP CHART Temporary Cone and Basket Strainers (TC, TB) KECKLEY This pressure drop chart is based on the flow of clean water through the Keckley Strainer Styles listed above with screen perforations ranging from 1/16” through 1/8”. TO USE CHARTS: Find your desired rate of flow (GPM) on the left hand side of the chart. Follow its corresponding horizontal line to the point where it

Crane Fluid Systems offers a full range of general valves, WRAS approved public health valves for hot and cold water systems and pipe fittings and unions, many of which carry the BSI Kitemark. ProBalance range offers a wide variety of Flow Management Systems and Static Balancing Valves, providing the ultimate in accuracy and reliability. Well documented pressure loss calculator for use with basket and tee style strainers.

Pressure drop in pipes.... PRESSURE DROP CALCULATIONS Pressure drop or head loss, occurs in all piping systems because of elevation changes, turbulence caused by abrupt changes in direction, and friction within the pipe and fittings. The most common methods used to determine the head loss in fiberglass pipe are Hazen-Williams, Manning and Darcy-Weisbach equations. The suitability of each calculation, for example you are missing the pressure drop across the cleaner, the properties of the fluid, etc. Figure 4 The control volume determines where the conditions on the suction side of the pump can be calculated. Figure 5 A system that requires a specified pressure at the inlet of an equipment.

pressure drop through the strainer will increase very rapidly, possibly causing damage to the screen. Screen openings other than those shown above are readily available. Various mesh sizes as fine as 5 micron and perforated plate as coarse as 1/2” Dia. are in inventory. Screens are available in a wide range of materials. Screens of carbon steel, stainless steel (304, 316), alloy 20, monel Strainers normally present low resistance to liquid flow. The pressure drop across most strainers is relatively small compared with the pressure drop across thick media filters or membrane filters. Another difference is the function. A strainer is used to protect other downstream equipment (e.g., pumps, instrumentation) from damage by rogue

KECKLEY COMPANY • 3400 Cleveland Street • Skokie, Illinois 60076 1-800-KECKLEY Y47 07/12 PRESSURE DROP CHART Flanged “Y” Pattern Strainers (Styles A, BA, BA-7, SA, SA-7, SSA and SSA-7) This pressure drop chart is based Pressure Drop Chart System fluid passing through a Spirovent or Spirotrap will create a certain pressure drop, depending on the size of the nozzles, diameter of the shell, and the volume (flow) and speed (velocity) of the fluid. Figures D-1 and D-2 (pages 3 and 4) show the pressure drops and water velocities for all product sizes up to

pressure drop through the strainer will increase very rapidly, possibly causing damage to the screen. Screen openings other than those shown above are readily available. Various mesh sizes as fine as 5 micron and perforated plate as coarse as 1/2” Dia. are in inventory. Screens are available in a wide range of materials. Screens of carbon steel, stainless steel (304, 316), alloy 20, monel PRESSURE DROP CHART Temporary Cone and Basket Strainers (TC, TB) KECKLEY This pressure drop chart is based on the flow of clean water through the Keckley Strainer Styles listed above with screen perforations ranging from 1/16” through 1/8”. TO USE CHARTS: Find your desired rate of flow (GPM) on the left hand side of the chart. Follow its corresponding horizontal line to the point where it

Y Strainers Screwed End S-MS-PressureDrop-Y 1341 © 2013 Mueller Steam Specialty Mueller Steam Specialty product specifications in U.S. customary units and … l) Determine the pressure drop (PI) through the strainer with water flow and standard screens. 2) If non-standard screens (i.e. 40 mesh, etc.) are being used, apply factors in Chart #1 to determine corrected pressure drop (P2). 3) Multiply PI or P2 (if used) by the specific gravity of the fluid actually flowing through the strainer to get P3.

The Pressure Drop Chart for Basket strainers indicates a drop of 0.9psi. The Screen openings chart indicates the % open area of 100 mesh is 30%. From chart one correction factor to be 1.2. Pressure drop in pipes.... PRESSURE DROP CALCULATIONS Pressure drop or head loss, occurs in all piping systems because of elevation changes, turbulence caused by abrupt changes in direction, and friction within the pipe and fittings. The most common methods used to determine the head loss in fiberglass pipe are Hazen-Williams, Manning and Darcy-Weisbach equations. The suitability of each

Step 1 Using FIGURE 1 or 2 determine the pressure drop through the strainer with water flow and standard screens = (P1) Step 2 If non-standard screens (i.e. 40 mesh, 60 mesh , etc..) are being used, apply factors in CHART 1 to determine corrected pressure drop = (P2) calculation, for example you are missing the pressure drop across the cleaner, the properties of the fluid, etc. Figure 4 The control volume determines where the conditions on the suction side of the pump can be calculated. Figure 5 A system that requires a specified pressure at the inlet of an equipment.

and high pressures. A Y strainer is a pressure . vessel. Its wall thickness can be analyzed and evaluated by different applicable standards. Every rugged Eaton Model 85 Y Strainer is designed to stand up the most demanding real world applications. Eaton heavy duty Model 85 Y . Strainers are furnished with high quality stainless steel screens that are carefully fabricated to fit the strainer Flow Rate Vs. Pressure Drop (Clean Screen) These curves are for clean baskets, without mesh liners – and with WATER flowing through the strainer. For mesh-lined baskets and/or other fluids, you must first compute a correction factor.

Model 85 Heavy-Duty Y Strainer W&O Supply Inc.

Technical brochure Strainers FA. Step 1 Using FIGURE 1 or 2 determine the pressure drop through the strainer with water flow and standard screens = (P1) Step 2 If non-standard screens (i.e. 40 mesh, 60 mesh , etc..) are being used, apply factors in CHART 1 to determine corrected pressure drop = (P2), Pressure Drop Calculations To accurately calculate the pressure loss for filters and strainers in a pipeline, proceed as follows: First calculate pressure loss using Cv factor formula at right; Take the pressure loss figure obtained in (1) and recalculate it using the ….

Model 85 Heavy-Duty Y Strainer W&O Supply Inc.

Calculate Pressure Drop in Filters and Strainers. pressures. However, the piping system in general should be designed to avoid liquid traps and reduce the risk of hydraulic pressure caused by thermal expansion. Install the strainer with the cover in downward position. Danfoss recommends replacement/cleaning of the strainer when the differential pressure loss, For basket strainers on pump suction it is advisable to calculate the design pressure based on operating conditions to establish hydro test pressure at shop or site in order to avoid a robust strainer construction which may be unacceptable to layout..

Select a strainer of the same nominal size as that of the piping to which it will be connected (nominal size of piping = nominal size of strainer). Please remember that using a strainer of a smaller nominal size increases the pressure loss of the strainer and may disable it from keeping specified pressure at … PRESSURE DROP CHART Temporary Cone and Basket Strainers (TC, TB) KECKLEY This pressure drop chart is based on the flow of clean water through the Keckley Strainer Styles listed above with screen perforations ranging from 1/16” through 1/8”. TO USE CHARTS: Find your desired rate of flow (GPM) on the left hand side of the chart. Follow its corresponding horizontal line to the point where it

v value is the flow of water in m3/h at a pressure drop in the strainer of 1 bar, ρ = 1000 kg/m3. 2) For direct fitting in pipeline. 3) For direct fitting on to valves. Single flanges with flange gaskets for FA 15 Single flanges with flange gaskets for FA 20 1) Staybolt set with gaskets 1) Only for code no. 036-0061. Type Strainer area cm2 • For fluids other than water, multiply the pressure drop (Δ P) obtained from the charts by the specific gravity of the fluid in question. • For mesh lined screens, multiply the pressure drop (Δ P) obtained from the charts by the corresponding correction factor shown in the Cv correction table.

Fig. 822 & 810 (922 & 910) Y-Type Strainers; Y-Type Strainers. See The Full Strainers Range Here Fig. 822 & 810 (922 & 910) Fig. 822 & 810 (922 & 910) Features & Benefits Higher Kv (flow factor) for reduced pressure drop compared to previous range. * Please refer to Datasheet for full technical information . Pressure Rating PN16. Product Material Cast/ Ductile Iron Titan Flow Control, Inc. also offers downloadable Pressure Drop Charts for your convenience. Click on the images to the right to download the Adobe PDF sheets for Titan FCI's Strainer and Check Valve models. For additional help determining the pressure drop for a Titan Flow Control product, please contact us.

22/12/2005 · I dont think that at 150% of open area there is going to be a significant pressure drop. When the strainer becomes clogged there will be a presure drop worth considering. Idelchik Ch8 Flow Resistance A Design Guide for ENgineers covers such devices with uniform openings that cross the flow path. I am a busy at the moment so cant do the The pressure loss across a strainer can be calculated using the system’s flow rate and the Cv factor for that strainer. For example, a 1" Model 72 simplex strainer with a perforated basket has a Cv factor of 22.5. In water service with a 30 gpm flow rate, it will have a 1.7 psi pressure drop (30 ÷ 22.5)2 = 1.7.

Pressure Drop Calculations To accurately calculate the pressure loss for filters and strainers in a pipeline, proceed as follows: First calculate pressure loss using Cv factor formula at right; Take the pressure loss figure obtained in (1) and recalculate it using the … Pressure drop curves are based on water flow with standard screens. See page 16 for correction factors to be used with other fluids and/or screen openings. 2. For Style 1 basket strainers multiply value obtained in figure 2 by 1.15 to obtain clean pressure drop. FIGURE 1 FIGURE 2 Threaded Basket Strainer Pressure Drop - Liquids (Sizes 1/ 2 - 1

Step 1 Using FIGURE 1 or 2 determine the pressure drop through the strainer with water flow and standard screens = (P1) Step 2 If non-standard screens (i.e. 40 mesh, 60 mesh , etc..) are being used, apply factors in CHART 1 to determine corrected pressure drop = (P2) Fig. 822 & 810 (922 & 910) Y-Type Strainers; Y-Type Strainers. See The Full Strainers Range Here Fig. 822 & 810 (922 & 910) Fig. 822 & 810 (922 & 910) Features & Benefits Higher Kv (flow factor) for reduced pressure drop compared to previous range. * Please refer to Datasheet for full technical information . Pressure Rating PN16. Product Material Cast/ Ductile Iron

Pressure Drop Charts - "Y" Type Strainers (Cast) THREADED AND WELD END "Y" TYPE STRAINERS (YS12, YS52, YS55, YS56, YS81, YS82, YS83, YS84, YS63, YS65) Flow Rate - GPM (Clean Screen Handling Water) Pressure Drop - PSI 11.52 345 678910152 345 6 7891001502 34 567891000 Size(in) ВЅ Вѕ1 1Вј 1ВЅ 22ВЅ3 4 10 9 8 7 6 5 4 3 2 1.5 1.0.9.8.7.6.5.4.2.15.1.3 vC FLANGED END "Y" TYPE STRAINERS (YS58, YS59 l) Determine the pressure drop (PI) through the strainer with water flow and standard screens. 2) If non-standard screens (i.e. 40 mesh, etc.) are being used, apply factors in Chart #1 to determine corrected pressure drop (P2). 3) Multiply PI or P2 (if used) by the specific gravity of the fluid actually flowing through the strainer to get P3.

v value is the flow of water in m3/h at a pressure drop in the strainer of 1 bar, ПЃ = 1000 kg/m3. 2) For direct fitting in pipeline. 3) For direct fitting on to valves. Single flanges with flange gaskets for FA 15 Single flanges with flange gaskets for FA 20 1) Staybolt set with gaskets 1) Only for code no. 036-0061. Type Strainer area cm2 Pressure drop (P2) = P1 X Sp. Gravity = 1.56 X 0.80 = 1.25 psi Sample calculation Using chart 2 multiply P2 by the appropriate component factor (CF) to get P3.

KECKLEY COMPANY • 3400 Cleveland Street • Skokie, Illinois 60076 1-800-KECKLEY Y47 07/12 PRESSURE DROP CHART Flanged “Y” Pattern Strainers (Styles A, BA, BA-7, SA, SA-7, SSA and SSA-7) This pressure drop chart is based Pressure Drop Calculations To accurately calculate the pressure loss for filters and strainers in a pipeline, proceed as follows: First calculate pressure loss using Cv factor formula at right; Take the pressure loss figure obtained in (1) and recalculate it using the …

PRESSURE DROP CHART Temporary Cone and Basket Strainers (TC, TB) KECKLEY This pressure drop chart is based on the flow of clean water through the Keckley Strainer Styles listed above with screen perforations ranging from 1/16” through 1/8”. TO USE CHARTS: Find your desired rate of flow (GPM) on the left hand side of the chart. Follow its corresponding horizontal line to the point where it On strainer devices all data published by Hays is for a new, unclogged strainer. The variation in materials that clog a strainer makes it virtually impossible to predict pressure drops for clogged strainers. In system design it is recommended that a reasonable allowance be made for an additional restriction above that of the clean strainer.

Flow Rate vs Pressure Drop Duplex Strainers Sure Flow

Pipe Flow Calculations Clarkson University. The pressure loss across a strainer can be calculated using the system’s flow rate and the Cv factor for that strainer. For example, a 1" Model 72 simplex strainer with a perforated basket has a Cv factor of 22.5. In water service with a 30 gpm flow rate, it will have a 1.7 psi pressure drop (30 ÷ 22.5)2 = 1.7., Pressure drop in pipes.... PRESSURE DROP CALCULATIONS Pressure drop or head loss, occurs in all piping systems because of elevation changes, turbulence caused by abrupt changes in direction, and friction within the pipe and fittings. The most common methods used to determine the head loss in fiberglass pipe are Hazen-Williams, Manning and Darcy-Weisbach equations. The suitability of each.

Fig. 822 & 810 (922 & 910) Y-Type Strainers Hattersley

Strainer pressure drop calculator EnggCyclopedia. servicing strainer C. Optional manual or auto blow-down Y Type Strainers - Threaded Y Type Strainers - Flanged Y Strainers Flow Rate Vs. Pressure Drop (Clean Screen) Note: These charts are for theoretical calculations ONLY. Please contact our office with your exact specifications and you will be provided with factory calculations. Pipe Flow Calculations . R. Shankar Subramanian . Department of Chemical and Biomolecular Engineering . Clarkson University . We begin with some results that we shall use when making friction loss calculations for steady, fully developed, incompressible, Newtonian flow through a straight circular pipe. Volumetric flow rate . 2 4 Q DV ПЂ.

22/12/2005В В· I dont think that at 150% of open area there is going to be a significant pressure drop. When the strainer becomes clogged there will be a presure drop worth considering. Idelchik Ch8 Flow Resistance A Design Guide for ENgineers covers such devices with uniform openings that cross the flow path. I am a busy at the moment so cant do the Pressure Drop Charts - "Y" Type Strainers (Cast) THREADED AND WELD END "Y" TYPE STRAINERS (YS12, YS52, YS55, YS56, YS81, YS82, YS83, YS84, YS63, YS65) Flow Rate - GPM (Clean Screen Handling Water) Pressure Drop - PSI 11.52 345 678910152 345 6 7891001502 34 567891000 Size(in) ВЅ Вѕ1 1Вј 1ВЅ 22ВЅ3 4 10 9 8 7 6 5 4 3 2 1.5 1.0.9.8.7.6.5.4.2.15.1.3 vC FLANGED END "Y" TYPE STRAINERS (YS58, YS59

On strainer devices all data published by Hays is for a new, unclogged strainer. The variation in materials that clog a strainer makes it virtually impossible to predict pressure drops for clogged strainers. In system design it is recommended that a reasonable allowance be made for an additional restriction above that of the clean strainer. Select a strainer of the same nominal size as that of the piping to which it will be connected (nominal size of piping = nominal size of strainer). Please remember that using a strainer of a smaller nominal size increases the pressure loss of the strainer and may disable it from keeping specified pressure at …

On strainer devices all data published by Hays is for a new, unclogged strainer. The variation in materials that clog a strainer makes it virtually impossible to predict pressure drops for clogged strainers. In system design it is recommended that a reasonable allowance be made for an additional restriction above that of the clean strainer. and represented in table V. As William Hooper [8] has not provided any details about the pressure drop due to Y-strainer, therefore pressure drop due to Y-strainer is calculated using equivalent length method as per details provided in Carrier system design manual [2]. Pressure drop due to straight pipe is calculated using equation (1). TABLE V

pressure drop through the strainer will increase very rapidly, possibly causing damage to the screen. Screen openings other than those shown above are readily available. Various mesh sizes as fine as 5 micron and perforated plate as coarse as 1/2” Dia. are in inventory. Screens are available in a wide range of materials. Screens of carbon steel, stainless steel (304, 316), alloy 20, monel Pipe Flow Calculations . R. Shankar Subramanian . Department of Chemical and Biomolecular Engineering . Clarkson University . We begin with some results that we shall use when making friction loss calculations for steady, fully developed, incompressible, Newtonian flow through a straight circular pipe. Volumetric flow rate . 2 4 Q DV π

Pressure drop (P2) = P1 X Sp. Gravity = 1.56 X 0.80 = 1.25 psi Sample calculation Using chart 2 multiply P2 by the appropriate component factor (CF) to get P3. a clean basket from curve on appropriate Pressure Drop Chart in the Technical Data Section (flanged end). At 1000 GPM of water the pressure drop is .4psi. As described above the multiplying factor for a 50% clogged basket is 2. The pressure drop is then .4psi x 2 = .8psi. S-MS-PressureDropClog Theoretical Pressure Drop Curve for Screen Clogging

Technical Information for Standard Cast Pipeline Strainers. Performing pressure drop calculations are essential for deciding which pipeline strainer is best for your liquid filtration application. Pressure drops for Models 30, 50, 510, 570 and 72 strainers are all available and in ISC Sales’ inventory. Crane Fluid Systems offers a full range of general valves, WRAS approved public health valves for hot and cold water systems and pipe fittings and unions, many of which carry the BSI Kitemark. ProBalance range offers a wide variety of Flow Management Systems and Static Balancing Valves, providing the ultimate in accuracy and reliability.

Strainers normally present low resistance to liquid flow. The pressure drop across most strainers is relatively small compared with the pressure drop across thick media filters or membrane filters. Another difference is the function. A strainer is used to protect other downstream equipment (e.g., pumps, instrumentation) from damage by rogue The pressure loss across a strainer can be calculated using the system’s flow rate and the Cv factor for that strainer. For example, a 1" Model 72 simplex strainer with a perforated basket has a Cv factor of 22.5. In water service with a 30 gpm flow rate, it will have a 1.7 psi pressure drop (30 ÷ 22.5)2 = 1.7.

Well documented pressure loss calculator for use with basket and tee style strainers. PRESSURE DROP CHART Temporary Cone and Basket Strainers (TC, TB) KECKLEY This pressure drop chart is based on the flow of clean water through the Keckley Strainer Styles listed above with screen perforations ranging from 1/16” through 1/8”. TO USE CHARTS: Find your desired rate of flow (GPM) on the left hand side of the chart. Follow its corresponding horizontal line to the point where it

Technical Information for Standard Cast Pipeline Strainers. Performing pressure drop calculations are essential for deciding which pipeline strainer is best for your liquid filtration application. Pressure drops for Models 30, 50, 510, 570 and 72 strainers are all available and in ISC Sales’ inventory. Step 1 Using FIGURE 1 or 2 determine the pressure drop through the strainer with water flow and standard screens = (P1) Step 2 If non-standard screens (i.e. 40 mesh, 60 mesh , etc..) are being used, apply factors in CHART 1 to determine corrected pressure drop = (P2)

Pressure drop (P2) = P1 X Sp. Gravity = 0.78 X 0.80 = 0.62 psi Sample calculation Using chart 2 multiply P2 by the appropriate component factor (CF) to get P3. On strainer devices all data published by Hays is for a new, unclogged strainer. The variation in materials that clog a strainer makes it virtually impossible to predict pressure drops for clogged strainers. In system design it is recommended that a reasonable allowance be made for an additional restriction above that of the clean strainer.

Pressure drop (P2) = P1 X Sp. Gravity = 1.56 X 0.80 = 1.25 psi Sample calculation Using chart 2 multiply P2 by the appropriate component factor (CF) to get P3. calculation, for example you are missing the pressure drop across the cleaner, the properties of the fluid, etc. Figure 4 The control volume determines where the conditions on the suction side of the pump can be calculated. Figure 5 A system that requires a specified pressure at the inlet of an equipment.